Automatic Facial Mask Production Line SED-MCX

The automatic facial mask production line is suitable for the production of facial masks of various shapes and sizes. It is a complete line for production including packaging with soft bags or hard bags.

Product Description

Introduction of Automatic Face Mask Production Line

The automatic facial mask production line is compatible with soft mask bags. It can eliminate the mask products that do not contain mask and the filling weight exceeding standard levels in the mask bag. Finally, the masks are sent out in a pile according to the setting, which is convenient for subsequent packaging.

The most important machines for producing facial masks are the folding machine and the filling machine. The folding machine folds the dry cloth into the mask bag; the filling machine fills the essence and prints the production date and seal. Then delivers to the packaging process.

Process of Face Mask Production

Facial mask production and filling → weighing and counting → cartoning → three-dimensional wrapping → box packing and sealing

Labeling machines, inkjet printers, etc. are optional according to customer needs.

Composition of Automatic Mask Production Line

Fully Automatic Mask Making Machine

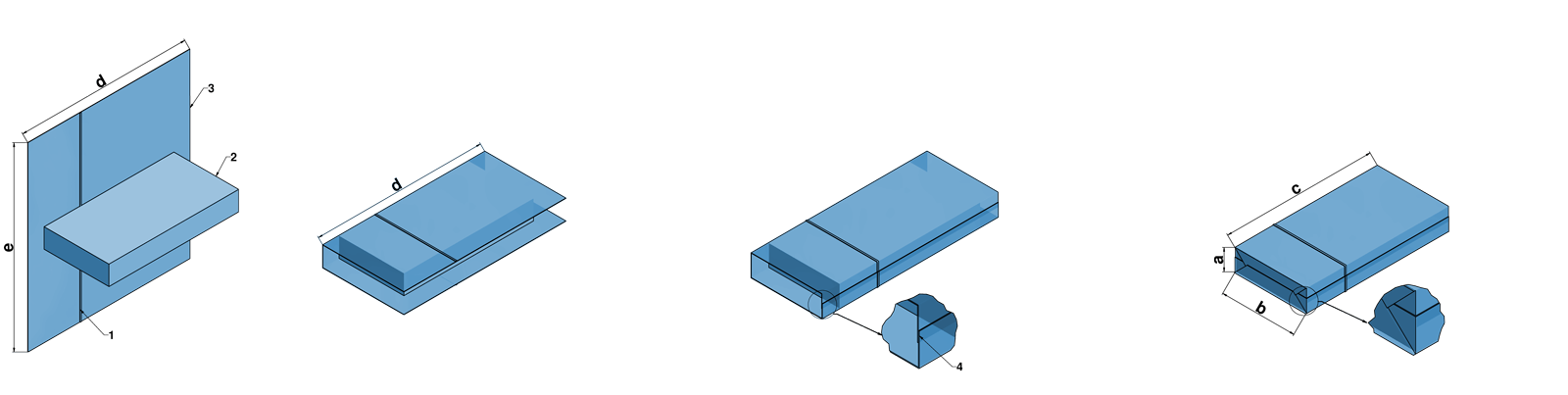

It can cut the film and fold it into the bag. 3 layers of film can be cut at the same time. It is suitable for simultaneous output and punching of various mask materials to ensure a better fit between the mask and auxiliary film.

Fills the liquid essence, and then seals and prints the production date. The filling accuracy is ±0.01g

Facial Mask Weighing Machine

The automatic mask machine tests the weight of the finished mask produced and the masks with unqualified weight levels will be rejected.

Mask Counting Machine

Counts masks according to the setting number (5-20 sheets), and then neatly pile masks up and sends them to the conveyor.

Automatic Cartoning Machine

The multifunctional automatic cartoning machine is suitable for automatic cartoning and packaging of products in the pharmaceutical, food, daily necessities, electronic components and other industries. It mainly completes folding and conveying, product cartoning, finished product conveying, waste rejection and so on.

Cellophane Overwrapping Machine

Used to pack a layer of the film outside the mask box. It is suitable for medicines, health products, food, cosmetics and tobacco industries, especially for medicines and health products with high-quality packaging requirements.

Fully Automatic Cartoning Line

It can automatically carry out the functions of carton unpacking, bottom folding, bottom tape sticking, and output.

Features of Face Mask Production Line

- Various mask production line solutions can be designed according to requirements

- Compatible with multiple mask bags

- One-key switch, no need to change mold

- Efficient and fast

- Filling, exhaust, sealing, coding, one-time molding

- PLC touch screen control, easily set parameters on the touch screen

- High productivity

- Can be filled with different liquids, easy to clean

- Detection system: No mask, no filling

- Save labor cost

- Online bag making, saving 30% of packaging material cost

- Parts contacting with materials are made of 316 stainless steel

Applications of Face Mask Production Line

It is suitable for the production of facial masks of various shapes and sizes and suitable for packaging both soft bags and hard bags.

Technical Data

| Machine Material | Q235+SUS304 (GMP standard) |

| Packing Speed | 50~60 bags/minute (the speed can be adjustable) |

| Liquid Filling Capacity | 10-58 ml *pump capacity is optional |

| Bag Size | H (75mm~225mm) W (75mm ~200mm) |

| Bag Material | CPP, PE, PET, BOPP Compound film, Aluminum Foil Film, Paper film Best Thickness: 0.08mm~0.12mm |

| Bag Type | three-side sealing flat bags |

| Sealing Temperature | 0-300℃ (adjustable) |

| Power Supply | 380V 50HZ 3.5kW, Three Phase |

| Air Pressure | 0.25 m³/min |

| Working Pressure | 0.6 MPa |

| Machine Net Size (L×W×H) | 2000×960×1700 mm |

| Machine Net Weight | 1100 kg |

| Machine Package Size (L×W×H) | 2280×1160×1900mm |

| Machine Gross Weight | 1200 kg |

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.