Automatic Soft Bag IV Solution Production Line

The non-PVC soft bag IV solution production line can automatically complete film feeding, printing, bag making, filling, and sealing

Product Description

Introductions of IV Solution Production Line

Automatic IV Fluid Filling Line is the highest efficiency aseptic product line. It can finish such procedure as printing, bag-making, bag-filling, and sealing. With the advantages of high productivity, good stability, and low error rates.

The advantages of Soft IV Bag

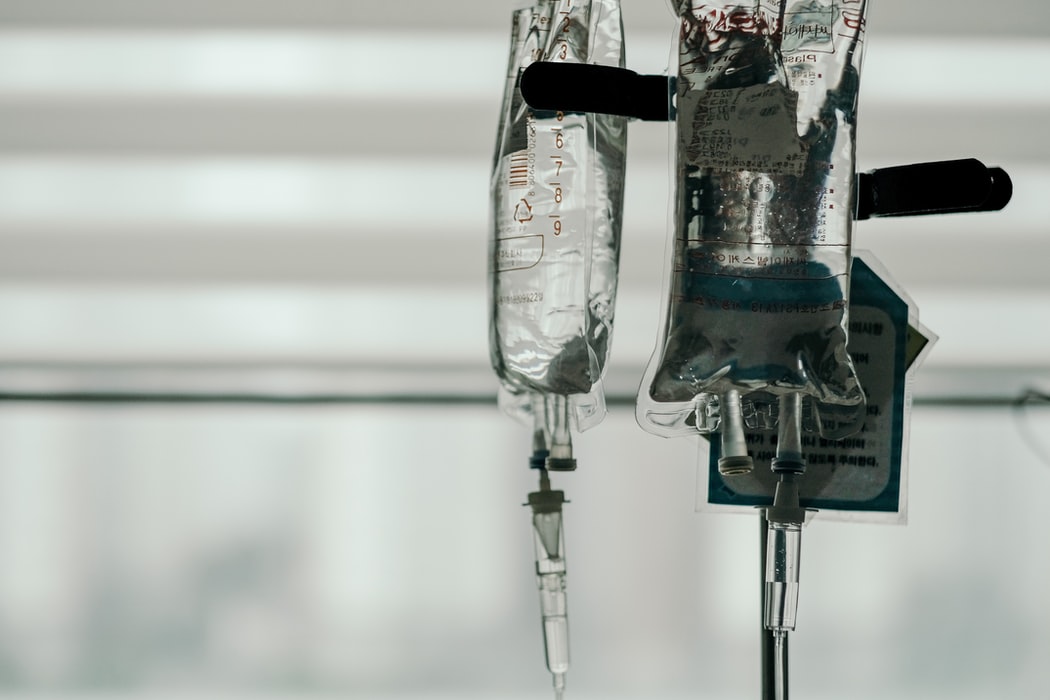

The flexible IV solution bag has many advantages compared to the glass bottle or blow molded plastic container. It is easy to handle, carry and store; it is collapsible which makes air vents redundant. Light in weight, small, and highly transparent.

Applications of IV Solution Production Line

The bag IV solution production line consists of three parts: forming, filling, and sealing.

IV Fluid Filling Line can be connected to other auxiliary equipment to form an integrated line.

It is suitable for 50ml-500ml infusion soft bag production in pharmaceutical factories, such as general solutions, special solutions, dialysis solutions, parenteral nutrition, antibiotics, irrigation solutions, and disinfectant solutions, etc.

Features of IV Solution Production Line

- The latest advanced technology, solid structure, stable and reliable

- Advanced touch screen operation, aptitude control time, temperature, pressure, and filling meter, etc. Parameters can be set and monitored by computer

- The machine has strong memory recall system. Aims at different film material, user can store practice welding parameters and set to use

- It can set automatically start up, set to warm-up machine, and guarantee enough running time

- Applicable to any round or flat IV solution bags with different shapes

- The filling system adopts mass flowmeter to metering, high precision and wide range for filling quantity, CIP/SIP online

- Precise arrangements. The server system, PLC, pneumatic elements and so on, all adopt international brands, assured to run steadily and reliably

- Its structure is unique, and the production efficiency is high, it can produce 6000 single chamber or multi-chamber soft bags every hour

- The production line integrates bag making, filling, and sealing into one, its length is compressed by 1/3, the area of the workshop and air-conditioner purifier are decreased by 1/3, so it can decrease the investment cost and maximize value

- In pharmaceutical production line for I.V. solutions, all components that contact with the filled liquid are made of stainless steel or nontoxic polypropylene material, which ensures that the liquid is not contaminated and meets the strict hygiene standards

Technical Data

| Order Code | SED-1200RY | SED-2500RY | SED-3500RY | SED-4500RY | SED-6000RY | ||||||||||||

| Max. Productivity | 1200 bags/h | 3500 bags/h | 6000 bags/h | ||||||||||||||

| Capacity | 100ml, 250ml, 500ml | 50ml, 100ml, 250ml, 500ml | |||||||||||||||

| Interface Methods | Boat Interface | Tube Interface | Boat Interface | Tube Interface | Boat | ||||||||||||

| Color Ribbon Dim | The standard chramatape with the inner diameter 3 in. and the outer diameter smaller than 140mm. | ||||||||||||||||

| Film Dimension | The standard film with the inner diameter 6 in. and the outter diameter smaller than 600mm | ||||||||||||||||

| Printing | Hot sheet , single color;T he producing date, validity, approval No. are simultaneously printed and easily changed. | ||||||||||||||||

| Power | 20kw | 6kw | 30kw | 7kw | 32kw | 8kw | |||||||||||

| Compressed Air Pressure | Dry and oil free compressda air, the cleaness in 5μm, the pressure is over 0.6Mpa , automatically stop and warning signals when it is too low. | ||||||||||||||||

| Compressed Air Consumption | 2400L/min | 3000L/min | 3500L/min | ||||||||||||||

| Clean Air Pressure | The neat air is over 0.4 MPa, and it’s cleanliness is 0.22μm. | ||||||||||||||||

| Clean Air Consumption | 600L/min | 1000L/min | 1400L/min | ||||||||||||||

| Cooling Water Pressure | >0.5kg/c | NONE | >0.5kg/c | NONE | >0.5kg/c | NONE | |||||||||||

| Cooling Water Consumption | 100L/h | None | 120L/h | None | 150L/h | None | |||||||||||

| Nitrogen Consumption | It can be protected with 0.6Mpa nitrogen by the special requirements, the consumption under 45L/min . | ||||||||||||||||

| Noise | |||||||||||||||||

| Room Requirements | The environmental temperature shall control in 24ºC, the relative humidity is unallowed over 50%, and the humidity is in 85%. | ||||||||||||||||

| Overall Size | 6.4m*2.5m*2.1m | 8.1m*4.7m*2.1m | 8.5m*2.7m*2.1m | 12.3m*4.7m*2.1m | 10.6m*2.4m*2.1m | 13m*4.7m*2.1m | |||||||||||

| Reference Workshop Dimensions | 8m*4.5m*2.4m | 10m*6.7m*2.4m | 10.0m*4.7m*2.4m | 14m*6.7m*2.4m | 12m*4.5m*2.4m | 14m*4.7m*2.4m | |||||||||||

| Weight | 7.6 ton | 10.8 ton | 12.0 ton | ||||||||||||||

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.