Automatic Soft Gelatin Encapsulation Machine for Sale

The automatic encapsulation machine can quantificationally inject the oil, mixing suspension or pasty mass into a capsule to form all kinds of soft gel encapsulation with different sizes, shapes, and colors.

Product Description

Introduction of Automatic Encapsulation Machine

Automatic encapsulation machine can quantificationally inject the oil, mixing suspension or pasty mass into a capsule to form all kinds of soft gel encapsulation with different sizes, shapes, and colors.

Application of Automatic Encapsulation Machine

Because of the merits of high-speed disintegration, easiness to swallow, hard to oxidize, easy to store and take, the soft gel encapsulation is welcomed by more and more customers. Owing to the high productivity rates, precision quantities, quality stabilization, and high finished product rate, soft gelatin encapsulation machine is favored by more manufacturers in the fields of medicine, health products, cosmetic and paintballs and so on.

Apply to filling of all substances which can not be melted in the water. Soft gelatin capsule filling machine is ideal for encapsulation of a multitude of products, including vitamins, herb’s, drugs, cosmetics, lubricants, and adhesives.

Features of Automatic Encapsulation Machine

- High production capacity, it can produce 5-9 million pieces per month (No. 8 oval shape, 10hours/day for 30days/month).

- Injecting medicine component adopts advanced linearity driving system and ensures the precision of charging and filling is accurate with less than 2% deviation.

- Capsule package rate is up to 98%.

- The gelatin ribbon is lubricated by fine oil supply technology to lower the consumption of lubrication oil. The ribbon is lubricated by vegetable oil, so the capsules produced is free of wash.

- High quality capsule deferent equipment adopts food conveyer belt authorized by American FDA, easy to clean and adverse to poisons or inhibitions.

- Optimized designed mould is made of high-quality aviation alloy material with high precision numerical control process to ensure the mould’s service life.

- Advanced process and assembly techniques make the complete appliance quality stabilized, high efficiency rate, and consistent well shaped pills.

- Adopts automatic system project of supplying capsule and material to reduce work labor intensity and improve the working environment, which complies to the requirement of GMP.

- The liquid level in the gelatin box is fixed automatically in the constant position and the centigrade mater display the thickness of the gelatin, which is easily adjusted to be accurate.

The Production of Soft Gelatin Capsules

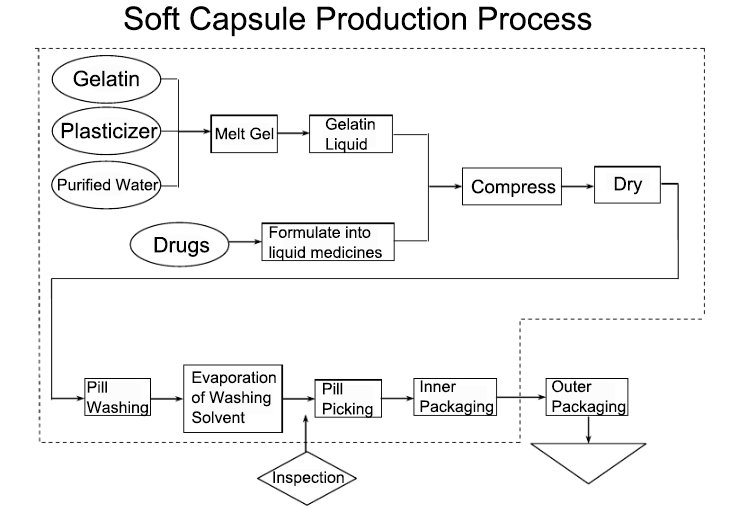

Its not easy to produce soft gel capsules, the main production process includes melting of gelatin, formulation, compression, drying, pill washing, pill picking, inner packaging, and outer packaging.

For the packaging of soft gel capsules, we have several choices:

- Use capsule counting line to count capsules into bottles, capping, labeling, etc.

- Use blister packing machine to pack capsules into aluminum plastic blister boards, and then carton machine automatically puts them into cartons.

For more detailed information about soft gel capsules, read the article Soft Gelatin Capsules VS Hard Gelatin Capsules.

Technical Data

| Parameters | Unit | Model | |||

| SED-200RJ | SED-250RJ | SED-300RJ | SED-110RJ | ||

| Rotary Speed of Die Roll | r/min | 0-7 | 0-5 | 0-5 | 0-7 |

| Supplying Volume for Flow Single-pillar Pistol | ml | 0-2 | 0-2 | 0-2 | 0-0.8 |

| Rolling Die Size | mm | φ103×200 | φ150×250 | φ150×300 | Φ72×110 |

| Noise | dBA | less than 75 | |||

| Power Supply | V, Hz | 380V50Hz | |||

| Total Power | kW | 5.5 | 8.3 | 8.9 | 3.8 |

| Weight | kg | 1100 | 1800 | 1900 | 700 |

| Overall Dimensions | mm | 1990×980×2040 | 2400x1170x2200 | 2400×1220×2200 | 1500×860×1700 |

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.