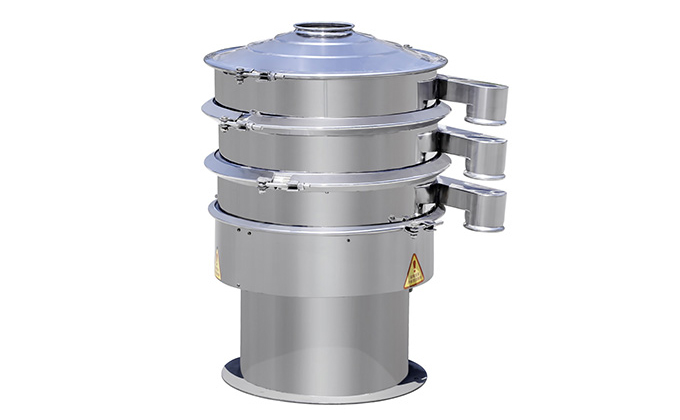

SED-SF Series Industrial Powder Sieving Machine

An industrial powder sieving machine uses a horizontal vibration motor or special vibration exciter as its vibration source.

Product Description

Description of Industrial Powder Sieving Machine

Industrial Powder Sieving Machine uses a horizontal vibration motor or special vibration exciter as its vibration source. The horizontal vibration motor and vibration exciter have an eccentric block at both their upper and lower sides. By adjusting the phase angles of the upper and lower eccentric blocks, the material on the sieving machine screen can change the movement locus, achieving suitable screening performance.

Features of Industrial Powder Sieving Machine

- The screening precision of our vibrating sand screening machine is excellent, and the blocking rate of the screen is less than 10% on average.

- The movement locus and vibration amplitude are both adjustable. Any granular, powdery, and serous materials could be roughly screened, or just filtered according to the material applications.

- The screening machine is 500-2000 mm in diameter, and the overall size is quite small. Wheels can be mounted on it for convenient moving.

- The screen frame of the circular vibrating screen is specially designed. It takes only 5-10 min for screen change. The stainless-steel wire woven net is easy to clean and operate, while the life span of the equipment is long.

- A completely enclosed structure is adopted so the particulate matter pollution in the air is limited.

- The discharging outlet can be rotated at 360 degrees, facilitating the installation of matching equipment.

- The energy consumption of our circular vibrating screen is small, while the noise level is as low as 73-80dB.

- During the operation, if a short circuit, phase loss or unstable voltage occurs, the motor will automatically cut off the power supply and stop working to make sure the motor will be not burnt out. This will ensure any electrical damage is reduced to a minimum or at extremely low levels.

- The protective grade of the motor complies with IP65, which means it is dustproof and waterproof. In addition, it is also heatproof and oilproof.

Applications of SED-SF Series Industrial Powder Sieving Machine

(Materials below are examples taken from an extensive list of products compatible with the equipment. For a complete list, please contact us.)

- Chemical Industry: resin pigment, medicine, grease, paint, palette, cosmetics, etc.

- Food Industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc.

- Metallurgy Industry: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electric magnetic material, polishing powder, refractory material, etc.

- Mining industry: kaoli, alumina, carbon, quartz sand, titanium oxide, zinc oxide, etc.

- Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

- Mechanical Industry: casting sand, powder metallurgy, electromagnetic material, metal powder, etc.

- Paper-Making Industry: coated slurry, exhaust liquid, paper-making liquid and wastewater reclamation, etc.

- Pollution Treatment: waste oil, wastewater, additives, activated carbon, etc.

Technical Data

| Model | Nominal Diameter (mm) | Screen Diameter (mm) | Screen Surface Area (m³) | Feeding Size (mm) | Specification | No. of Layers | Frequency (rpm) | Power (kW) |

| SED-400SF | 400 | 340 | 0.09 | 2-325 | 1-5 | 1500 | 0.18 | |

| SED-600SF | 600 | 530 | 0.22 | 0.25 | ||||

| SED-800SF | 800 | 720 | 0.4 | 0.55 | ||||

| SED-1000SF | 1000 | 900 | 0.63 | 0 | 0.75 | |||

| SED-1200SF | 1200 | 1100 | 0.95 | 0 | 1.1 | |||

| SED-1500SF | 1500 | 1400 | 1.5 | 0 | 1.5 | |||

| SED-1800SF | 1800 | 1710 | 2.3 | 0 | 2.2 | |||

| SED-2000SF | 2000 | 1910 | 2.86 | 0 | 3.7 |

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.