Antibiotic Vial Powder Filling & Stoppering Machine

Antibiotic powder filling and stoppering machine is a unique sterile powder filling machine, it is used for filling powder into containers, for example, antibiotic vials.

Product Description

Description of Antibiotic Powder Filling and Stoppering Machine

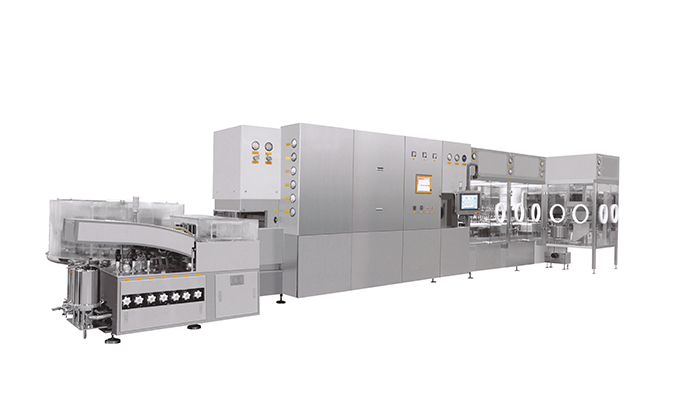

Antibiotic powder filling and stoppering machine is a unique sterile powder filling machine, it is strictly manufactured with GMP standards, and used for antibiotic, sterile, and aseptic powder packing for vials and bottles. This machine is equipped with a laminar flow hood, and it can be equipped with RABS, and an isolator according to customer requirements.

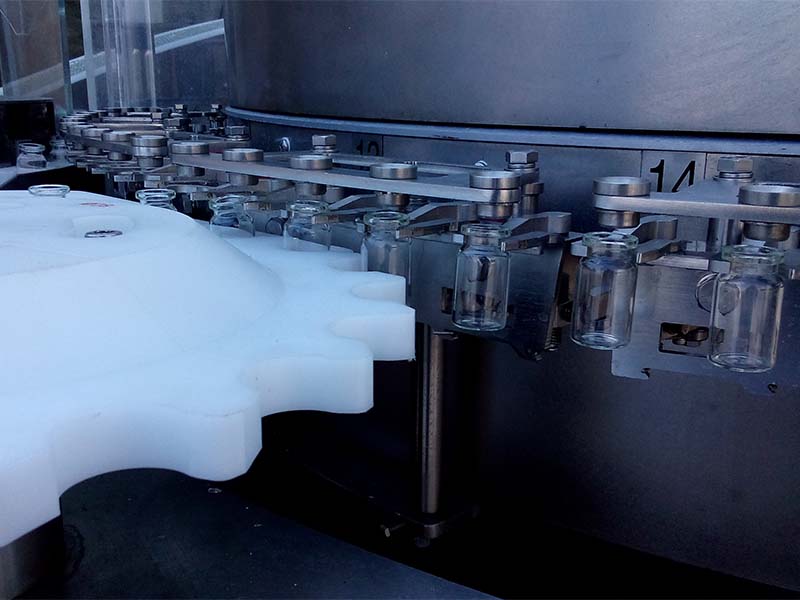

The machine consists of a turntable, graduator, filling head, stoppering device and bottle outlet track. The turntable and stainless-steel chain are used to transfer the bottles, and the stepping motor is used to drive the filling auger. The powder injectable equipment adopts 2/4 filling heads and 1-2 stoppering heads and the machine adopts a graduator system to achieve a high-speed filling process.

Working Process of Antibiotic Powder Filling and Stoppering Machine

The stainless-steel chain sends the vial to the graduator, then the powder conveying screw and the filling auger fill the powder into the vial according to pre-set step number. The stoppering device adds a stopper on the vial when filling is finished and the vial is sent to stoppering position during the stop time of the graduator.

Features of Antibiotic Powder Filling and Stoppering Machine

- Small volume, suitable for pharmaceutical companies with smaller production capacities and less floor space

- Compact cGMP model

- All the contact parts are made of SUS316L

- High filling speed, driven by servo motor

- Different type of filling auger meets requirements of different powder fluidity

- PLC control the whole process, high degree of automation

- Touch panel control: can set the filling dosage without stopping the machine

- Speed controlled by inverter

- Falling bottle auto reject; no bottle, no filling; no stoppers, auto stops; insufficient stoppers alarm

- Auto counting function

- Standard electric installation, safety guarantee on operation

- Auto stop filling when filling auger touches filling nozzle and alarms

- Easy to change the part, adjustable filling dosage

- Optional acrylic glass hood, laminar flow, sealed air outlet device

- Optional pre-fill and after-fill nitrogen filling device

Technical Data

| Suitable Bottle Range | 7~30ml (tubular or molded vial),50ml, 100ml |

| Speed | 45-80 bottles/min as per 30ml bottle |

| Power Supply | 220V 50Hz |

| Total Power | 3kw |

| Filling Error | ≤2% |

| Auto Stoppering Ratio | ≥99.7% |

| Bottle Breakage Ratio | ≤0.1% |

| Single Machine Noise | ≤70dB |

| Vacuum Degree | -6×10-2Mpa 14m3/h |

| Weight | 800kg |

| Dimension | 2850×1000 ×1800(mm) |

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.