Automatic Injectable Vial Powder Filling Line

The aseptic vial powder filling line consists of the ultrasonic bottle washing machine, tunnel dryer, turntable, pharmaceutical vial filling stoppering machine and vial capping machine.

Product Description

Ampoule & Vial Washing Machine

The entire exterior of the cleaning area is made of stainless steel (material: AISI 304). It is driven by an infinitely variable d.c. motor. Pipes, fittings, connections, and diaphragm valves are of the tri-clover clamp design suitable for pharmaceutical use.

The automatic rotary bottle washing machine can be used for bottle washing of glucose, antibiotic, amino acid, fat emulsion, nutrient solutions and biological agents and other medical liquids (like tincture liquid) etc.

Sterilizing Tunnel for Ampoules and Vials

According to the GMP standard for pharmaceutical production, the vials, ampoules, antibiotic bottles, and oral liquid bottles need to be dried and sterilized immediately after being rinsed. There are generally two methods of disinfection and sterilization: damp heat and dry heat. Combining the above-mentioned cleaned bottles requires drying treatment, so using a drying sterilization box, dry heat is one of the earliest applications, the most reliable in terms of effectiveness, and the most widely used method.

Sterilizing and drying tunnel is suitable for drying and sterilizing ampoules, antibiotic vials, oral medical liquid bottles as well as other medical glass bottles.

Under the control of the PLC program, the bottles will enter the preheating zone, high-temperature zone and cooling zone in sequence along the conveyor belt. The speed of the conveyor belt is electronically adjustable, and the temperature is adjusted and monitored by the color display. After drying and sterilization, the bottle automatically enters the follow-up equipment of the production line. The whole process can be monitored and operated by the display screen. The temperature monitoring system can be set, displayed, monitored, recorded, and printed.

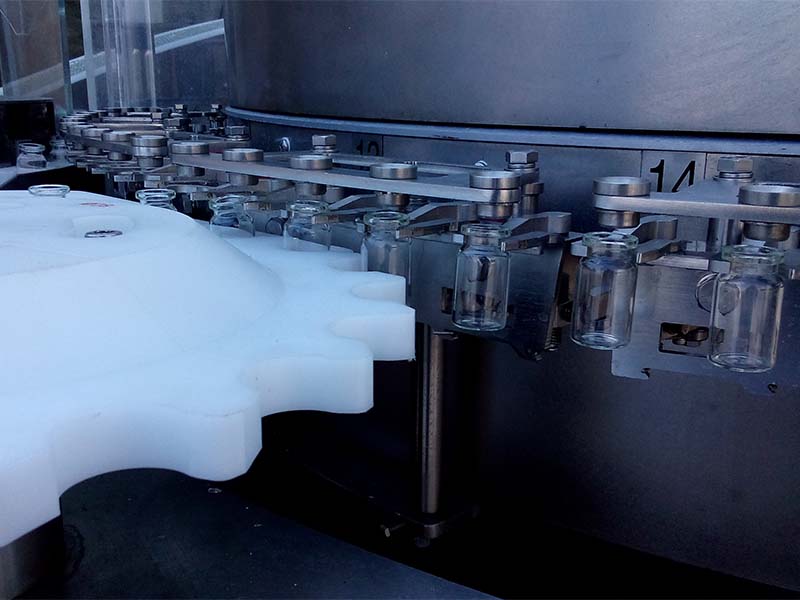

Infeed Turntable

Bottle infeed turntable plays the role of sorting and storing bottles in production. At the same time, it is applied to the connecting and buffering of the sterilizing and drying tunnel and the filling machine, the device has a sensor and the front and rear machines to form a production line.

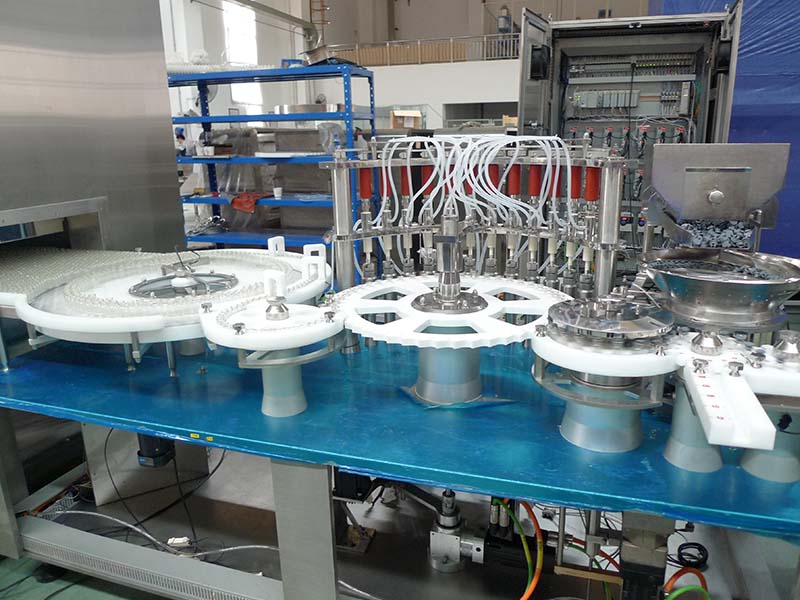

Vial Powder Filling And Stoppering Machine

A vial powder filling machine can be used for aseptic powder packaging with a hundred-level laminar flow, it has a compact design, and complete functions.

Vial Capping Machine

The vial capper machine is placed around the main star-wheel and will apply the alu-cap on filled and stoppered vials.

Technical Data

| Product Filling Head | 6 Heads | 8 Heads | 10 Heads | 12 Heads | 16 Heads |

| Suitable Size | 2-30ml(vial) | ||||

| Production Capacity (pcs/min) | 60-200 | 100-250 | 120-300 | 150-400 | 200-500 |

| Power Supply | 380V 50HZ | ||||

| Power Capacity (kw) | 90 | 92 | 108 | 108 | 115 |

| Total Weight (kg) | 8800 | 9300 | 9900 | 10200 | 10800 |

| Overall Size (mm) | 9700*2200*2450 | 9700*2200*2450 | 10850*2200*2450 | 10850*2200*2450 | 11770*2200*2450 |

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.