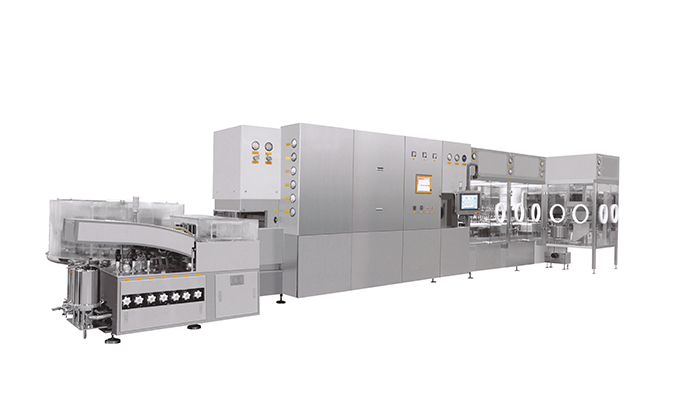

Sterilizing and Drying Tunnel for Vial and Ampoule

This equipment is applied for drying, sterilizing, and dehydrogenating washed vials, ampoules, and various other containers.

Product Description

Introduction of Sterilizing and Drying Tunnel

This sterilizing and drying tunnel has an integral tunnel structure. It’s divided into three parts: preheating zone, heating zone, and cooling zone. It adopts the hot air laminar flow sterilizing principle to sterilize and dehydrogenate containers in a short time.

Working Process of Sterilizing and Drying Tunnel

When the clean vials are sent into the sterilizing & drying tunnel automatically, they will be sterilized and dried in the airtight tunnel. After the vials are preheated, they will go to the heating zone, the temperature will be increased to nearly 320℃ (can be adjusted) to complete dehydrogenation, then the vials will be sent to the cooling zone to be cooled, and then be sent to the filling & stoppering machine.

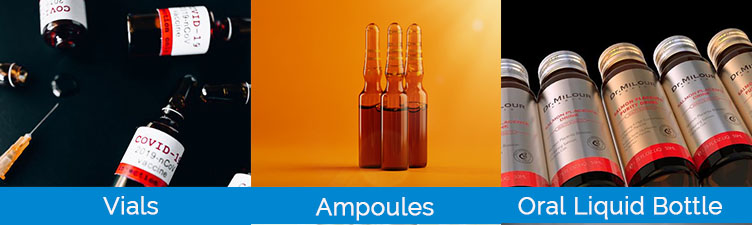

Applications of Sterilizing and Drying Tunnel

This bottle sterilizer and dryer are applied for drying, sterilizing, and dehydrogenating washed vials, ampoules, and various other containers.

Features of Sterilization and DryingTunnel

- Automatic air intake, adjustment of air volume, temperature, moisture, and air pressure

- Made in accordance with GMP standard

- Proven dry-heat sterilization following the unidirectional airflow principle

- Customer-specific tunnel design thanks to a modular system

- Fully automated transport system

- Flexible pressure zone concept for safe processes

- Easy integration to complete production lines

Technical Data

| Model | SED-4XGZ | SED-5XGZ | SED-6XGZ | SED-7XGZ | SED-8XGZ | SED-9XGZ |

| Power supply | 3 phases, 380V/50Hz | 3 phases, 380V/50Hz | 3 phases, 380V/50Hz | 3 phases, 380V/50Hz | 3 phases, 380V/50Hz | 3 phases, 380V/50Hz |

| Power | 28 kW | 56kW | 86kW | 95kW | 180kW | 210 kW |

| Deviation (unload) | ≤ ±5 | ≤ ±5 | ≤ ±5 | ≤ ±5 | ≤ ±5 | ≤ ±5 |

| Air intake | 500 m³/hr | 500 m³/hr | 500 m³/hr | 500 m³/hr | 500 m³/hr | 800 m³/hr |

| Exhaust | 2500m³/hr | 3900m³/hr | 5500m³/hr | 8300m³/hr | 9500m³/hr | 1000m³/hr |

| Water consumption | 2 m³/hr 6-9ºC cooling water | 2-3 m³/hr 6-9ºC cooling water | 3-4 m³/hr 6-9ºC cooling water | 4-5 m³/hr 6-9ºC cooling water | 4-5 m³/hr 6-9ºC cooling water | 5-6 m³/hr 6-9ºC cooling water |

| Output temperature | 30-35ºC | 30-35ºC | 30-35ºC | 30-35ºC | 30-35ºC | 30-35ºC |

| Dimensions | 2200 × 1450 × 2200 | 3400 × 1620 × 2200 | 4300 × 1850 × 2200 | 5000 × 2000 × 2200 | 6500 × 2200 × 2200 | 8000 × 2650 × 2350 |

| Feeding height | 900±20mm | 900±20mm | 900±20mm | 900±20mm | 900±20mm | 900±20mm |

| Weight | 1800kg | 2300kg | 3000kg | 3500kg | 4500kg | 7000kg |

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.