Industrial Glass Bottle Sterilizing Hot Air Drying Oven

This bottle sterilizer and dryer is suitable for vials, infusion bottles and all kinds of glass bottles requiring drying and sterilization.

Product Description

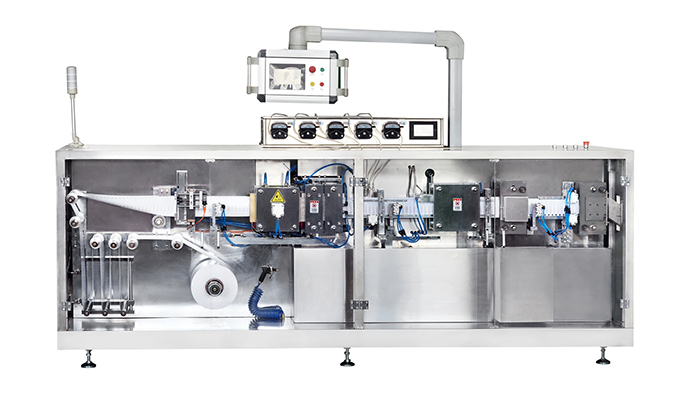

Introduction of Hot Air Drying Oven

Hot air drying oven uses electric heating as the heat energy: The energy generated by the electric heating elements, the use of a hot air circulating fan oven heating section of class 100 clean air inside the bottle during the convective heat exchange cycle, the required sterilization of the bottle is attained through the heat transfer, and continuous supply of fresh air, while eliminating air or saturated humid chamber heat which achieves drying of the items and finished sterilized bottles.

Features of Hot Air Drying Oven

- All the inner components of the cavity, which may possibly be in contact with the article is made of imported 316L stainless steel material.

- The outer surface is made of imported 304 stainless-steel material, and a new manufacturing technology is used to comply with GMP requirement and make the appearance more simple and aesthetic.

- The advanced technology can realize the dynamic 100-grade and superior temperature uniformity for the dry-heat sterilization ovens.

- The inner cavity room is well welded by adopting TIG welding technology, the four corners of inner cavity adopt an arc transition structure, and they can be cleaned easily without dead corners.

- The bottle sterilizer and dryer adopts an advanced full automatic control system, therefore the temperature is controlled automatically and the positive pressure is obtained automatically in the inner cavity.

- The special temperature-over protection system can secure the equipment effectively.

- The various cooling type processes can improve the work efficiency.

Application of Hot Air Drying Oven

This series of products are mainly used to dry, sterilize, and remove-pyrogen for heat resistant articles such as penicillin bottles, aluminum caps, metal and glass vessels in the pharmaceutical industry.

Technical Data

| Production Capacity (bottles/min) | 50~360 bottles/min |

| Belt Width (mm) | 500~1200 |

| Heating Mode | Far infrared quartz tube radiation heating |

| Cooling Mode | Class 100 vertical laminar flow cooling |

| Temperature Adjustment Range | 50~350℃ |

| Exhaust Air Rate (m³/h) | 9000~13000 |

| Voltage | 380V 50Hz three-phase four-wire |

| Power (kW) | 20~65 |

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.