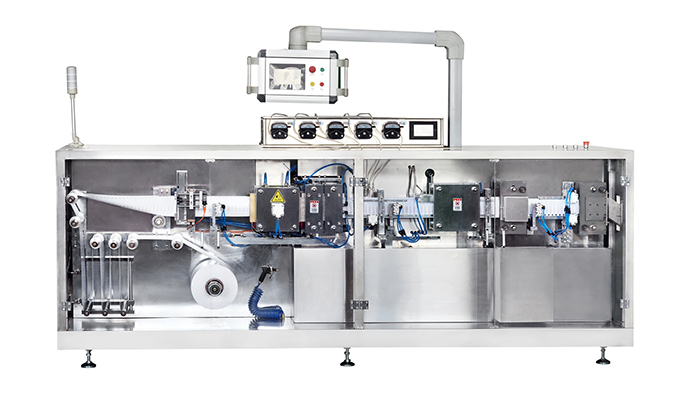

SED-GX Oral Liquid Vial Automatic Filling and Stoppering Machine

This automatic liquid filling machine is one of the traditional filling stoppering and capping equipment. It comes with an advanced design, reasonable structure, can automatically complete the filling, stoppering and capping process for vials.

Product Description

Introduction of Automatic Liquid Filling Machine

This automatic liquid filling machine is one of the traditional filling stoppering and capping equipment. It comes with an advanced design, reasonable structure, can automatically complete the filling, stoppering and capping process for vials. It can be used as stand-alone equipment or as a part of a complete production life. Easily connect with bottle capping machine, labeling machine and other equipment. This machine complies with the new GMP requirements.

Operation of Automatic Liquid Filling Machine

Bottles are fed on to an in-built Infeed turn table, from where it is delivered to SS conveyor belt. Conveyor belt transport bottles to filling station. Filling station has Pneumatic bottle stopper for exact bottle neck centering of bottles during filling operation

Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming, adjustable nozzle is reciprocating according to filling dose.

The dosing block has a hexagonal bolt, this means different fill sizes can be set easily within minimum use of time. After, liquid filling bottles are delivered to capping/labeling machine conveyor for further operations.

Features of Automatic Liquid Filling Machine

- Each stand-alone machine can be operated independently or be linked.

- PLC control, touch bottle operation, simple and convenient operation

- The use of international famous brand electrical components, well known for performance and stability

- The linear production line can be applied to the production of a variety of bottles by changing a small number of parts, and adjustment is simple

- According to customer needs, customize the production of 2 heads, 4 heads, 6 heads, 8 heads or 12 heads

- Plastic bottles and glass bottles are customized according to customer requirements

- Compact GMP model

- Detection systems: “No Bottle – No Fill” System, “No Bottle – Machine Stop” System

Application of Automatic Liquid Filling Machine

The automatic filling and stoppering machine is suitable for eye drops, juice, and other liquid filled vial/bottle products.

Technical Data

| Model | SED-4GX | SED-6GX | SED-8GX | SED-16GX |

| Applicable Specifications (ml) | 10-500 | 60-500 | 500-1000 | 500-1000 |

| Production Capacity (bottles/minute) | 10-40 (depends on the size of the bottle mouth) | 20-40 (depends on the size of the bottle mouth) | 10-20 (depends on the size of the bottle mouth) | 60-80 (depends on the size of the bottle mouth) |

| Top Cover Rolling Speed (bottles/minute) | 10-40 | 20-40 | 10-20 | 60-80 |

| Power Supply | 220V 50HZ | 380/220V 50HZ | 380/220V 50HZ | 380/220V 50HZ |

| Bottling Coverage | >99% | |||

| Weight | ≈980kg | |||

| Machine Size L × W × H (mm) | 2160*1200*1500 | |||

| Application | round bottles such as glass bottles and plastic bottles (can be customized according to the different bottles’ character) | |||

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.